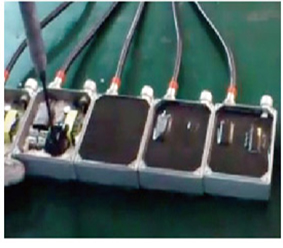

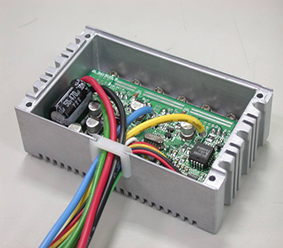

It is mainly used for filling and sealing of high-power electronic components, module power supply with high requirements for heat dissipation and temperature resistance, and circuit board with incomplete sealing, which plays the role of bonding, sealing, water-proof and moisture-proof. Such as switching power supply, transformer, power module, automobile hid power supply, automobile ignition system module power supply, network transformer, etc. As well as the filling and sealing of electronic components such as circuit boards which are not fully sealed, it plays the role of bonding, sealing, water-proof and moisture-proof.

* because the colloid contains fillers and heat conducting materials, the colloid placed for a long time will be layered and the filler will precipitate. Before use, mix the A / B components evenly, and then put them into the mixing tank according to the mass ratio of 10:1.

* pour the mixed rubber into the device to be potted. Generally, vacuuming is not necessary. If conditions permit, it is recommended to refill after vacuuming. This product is room temperature curing type. The curing speed of adhesive has no great relationship with curing temperature, but has a great relationship with the proportion content of agent B. the larger agent B is, the faster the curing speed is (it is suggested that the adjustment range of agent B is 100:7-100:12). Generally, it takes about 8 hours to cure at room temperature.

* Unused rubber materials shall be sealed for storage. The storage period is 6 months (25 ℃). The mixed rubber should be used up once to avoid waste.

* this product is not dangerous, but it is not allowed to enter or eyes.

* transportation: no domestic (cn-gb), International (IMO, IATA, UN) regulations. Non dangerous goods.

Before curing: ① external view: Black (a) / transparent (b) fluid; ② color after mixing: Black (b); ③ viscosity of component a (MPa. S, 25 ℃): 3500-5500 (adjustable) & nbsp;

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ④ viscosity of component B (MPa. S, 25 ℃): 20-40

Operating performance: ① two component mixing ratio (weight ratio) a: B -- 100: 10 & nbsp; MPa. S: 2500-4000 & nbsp; ③ surface drying time & nbsp; (min, 25 ℃): 50-70 (adjustable)

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ④ curing & nbsp; time & nbsp; (min, 25 ℃): 240-480 (adjustable) & nbsp; ⑤ curing & nbsp; time (min, 80 ℃)

After curing: ① hardness (Shore A): 30-40 & nbsp; ② thermal conductivity [w (M & middot; K)]: 0.4-0.6 & nbsp; ③ dielectric strength (kV / mm): & Ge; 22 & nbsp; ④ dielectric constant (100MHz): 3.0-3.4

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ⑤ volume resistivity (& omega; & middot; cm): & Ge; 1.0 & times; 1015 ⑥ elongation at break (%): 100-150 & nbsp; ⑦ maximum tensile strength (kgf / cm2): 1.6

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ⑧ operating temperature range (℃): - 50 ℃ - 200 ℃

Cs-9808 is a two-component silicone sealant with the following characteristics:

* component a of this product is a black viscous liquid and component B is a transparent liquid. The two components can be stored for a long time before mixing.

* this product has good heat conduction (heat dissipation), insulation, elasticity, corrosion resistance, weather resistance and other characteristics. After curing, the colloid can be used in a wide temperature range.

* no shrinkage during curing, good waterproof, moisture-proof and anti-aging properties.

* meet the requirements of EU ROHS directive.

Official website of mobile phone

Official website of mobile phone WeChat public address

WeChat public address