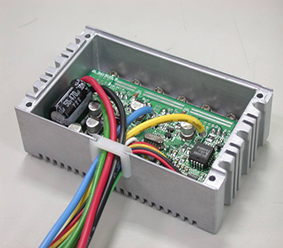

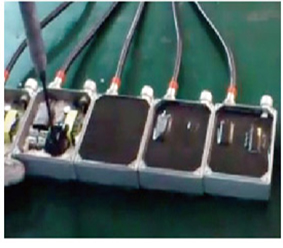

It is mainly used for potting protection of module power supply and circuit board with high power electronic components and high requirements for heat dissipation and temperature resistance. Such as switching power supply, transformer, power module, automobile hid power supply, automobile ignition system module power supply, network transformer, etc.

* due to the fire-retardant and heat-conducting materials contained in the colloid, the colloid placed for a long time will be layered and the filler will precipitate. Before use, mix the A / B component evenly, and then put it into the mixing tank according to the mass ratio of 1:1.

* pour the mixed rubber into the device to be potted. Generally, vacuuming is not required. If high thermal conductivity is required, it is recommended to refill after vacuuming. It can be cured at room temperature or heating. The curing speed of the adhesive is closely related to the curing temperature, and the curing time will be prolonged when the temperature is low. It is recommended to cure by heating, curing at 80 ℃ for 15-30 minutes, and curing at room temperature generally takes about 5 hours.

* Unused rubber materials shall be sealed for storage. The storage period is 10 months (25 ℃). The mixed rubber should be used up once to avoid waste.

* this product is not dangerous, but it is not allowed to enter or eyes.

* transportation: no domestic (cn-gb), International (IMO, IATA, UN) regulations. Non dangerous goods.

* the following chemicals may cause poisoning in the glue solution (trace of the following substances will not affect the curing): (poisoning: the glue cannot be cured) < br / >

&Middot; N, P, s organic compounds.

&Middot; ionic compounds of Sn, Pb, Hg, as and other elements.

&Middot; alkynes and polyvinyls.

&Middot: in order to avoid the above phenomenon, try to wipe the residual rosin on the circuit board and try to use solder with low lead content.

Before curing: ① external view: grey (a) / white (b) fluid; ② color after mixing: grey (b); ③ viscosity of component a (MPa. S, 25 ℃): 4200-4500 (adjustable) & nbsp;

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ④ viscosity of component B (MPa. S, 25 ℃): 4200-4500 (adjustable)

Operating performance: ① two component mixing ratio (weight ratio) a: B -- 1: 1 & nbsp; ② viscosity after mixing & nbsp; (MPa. S): 4200 ~ 4500 (adjustable) & nbsp; ③ surface drying time & nbsp; (min, 25 ℃): 30 ~ 50 (adjustable)

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ④ curing time & nbsp; (min, 25 ℃): 120-180 (adjustable) & nbsp; ⑤ relative specific gravity: 1.55 & plusmn; 0.05

After curing: ① hardness (Shore A): 45 & plusmn; 5 & nbsp; ② thermal conductivity [w (M & middot; K)]: 0.5-0.7 & nbsp; ③ dielectric strength (kV / mm): & Ge; 18 & nbsp; ④ dielectric constant (100MHz): 2.8-3.0

&Nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; ⑤ volume resistivity (& omega; & middot; cm): & Ge; 1.0 & times; 1013 ⑥ linear expansion coefficient (& nbsp; [M / (M & middot; K)]: & le; 2.2 & times; 10-4 & nbsp; ⑦ flame retardant grade: 94v0

Cs-9813g potting adhesive is a two-component addition molding flame-retardant and heat-conducting silicone potting adhesive with the following characteristics:

* component a of this product is gray viscous liquid, component B is white viscous liquid. The two components can be preserved for a long time before mixing.

* this product has good heat conduction (heat dissipation), insulation, elasticity, corrosion resistance, weather resistance, flame retardant and other characteristics. After curing, the colloid can be used in a wide temperature range.

* no shrinkage during curing, good waterproof, moisture-proof and anti-aging properties.

* meet the requirements of EU ROHS directive.

Official website of mobile phone

Official website of mobile phone WeChat public address

WeChat public address