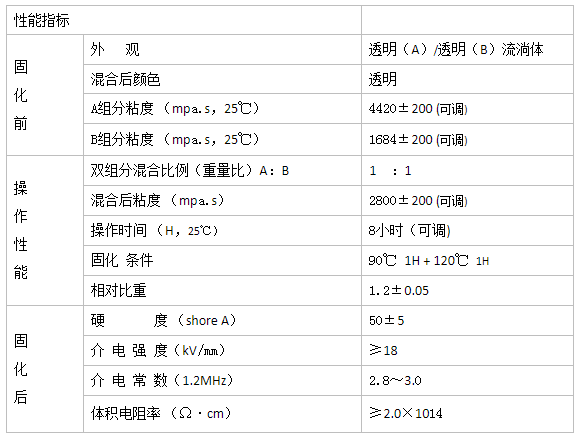

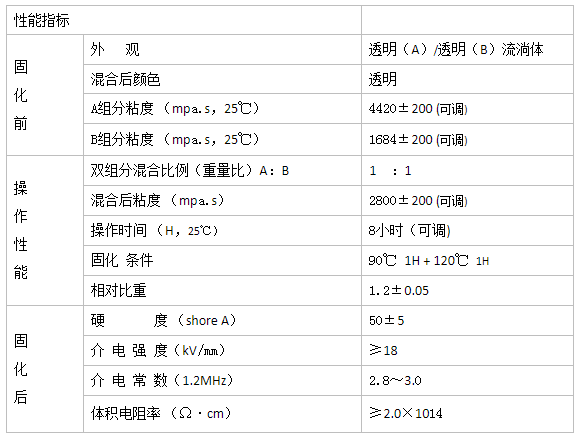

Cs-9813c is an addition molding medium temperature curing silicone potting adhesive. It is a special potting silicone for G9 halogen lamp potting silicone corn lamp, G4 / G9 and so on. After curing, the gel has good elasticity, high and low temperature resistance, strong adhesion, no cracking, no hardening, high transmittance, good thermal stability, small stress and low moisture absorption.

Usage and precautions:

1. Mix the glue of components a and B evenly according to the proportion of 1:1 by weight; (make sure that no other impurities are brought in when mixing the glue, Zui is good at using clean special containers and mixing rods);

2. Put the mixed glue into the foam exhausting device for foam exhausting, and then fill and seal it after the bubbles are eliminated; (because the surface tension of silica gel is low, the colloid is easy to overflow the container during the foam exhausting process, so Zui is good at using a container with four times the volume of colloid or using intermittent foam exhausting method for foam exhausting, that is to say, in the vacuum state for 10 seconds, after the bubbles accumulate, close the vacuum machine quickly , so that it can return to normal pressure, so that after repeated several times, the bubbles can discharge the colloid without overflowing the container);

3. Pour the foam discharged glue into the special mold, bake at 90 ℃ for 1 hour after sealing, and then raise the temperature to 120 ℃ for 1 hour. After the glue is completely solidified, let it naturally cool to normal temperature for subsequent operation;

Note: the whole operation is recommended to be carried out in a dry and dust-free environment.

Special reminder

* Unused rubber materials shall be sealed for storage. The storage period is 10 months (25 ℃). The mixed rubber should be used up once to avoid waste.

* this product is not dangerous, but it is not allowed to enter or eyes.

* transportation: no domestic (cn-gb), International (IMO, IATA, UN) regulations. Non dangerous goods.

* the following chemicals may cause poisoning in the glue solution (trace of the following substances will not affect the curing): (poisoning: the glue cannot be cured) < br / >

&Middot; N, P, s organic compounds.

&Middot; ionic compounds of Sn, Pb, Hg, as and other elements.

&Middot; alkynes and polyvinyls.

&Middot: in order to avoid the above phenomenon, try to wipe the residual rosin on the circuit board and try to use solder with low lead content.

Characteristic:

* components a and B of this product are transparent and viscous liquid, which can be preserved for a long time before mixing;

* it has excellent high and low temperature resistance and can be used in the range of (- 40-280 ℃);

* excellent adhesion, good adhesion to PCB and most metals;

* excellent light transmittance and refractive index, light transmittance > 96%, refractive index > 1.41;

* it has the characteristics of small stress and low moisture absorption, which can greatly guarantee the stability of light after sealing.

Official website of mobile phone

Official website of mobile phone WeChat public address

WeChat public address